I own a 1956 Cat D2 5U and have always wanted to get a winch mounted to use for pulling logs. The opportunity to purchase a Hyster D2N came about when I got a phone call from Chad Enyeart saying he knew where a nice one for sale was located. The price was fair but the big question was getting it from California to Georgia. We soon had that arranged and it arrived at my shop shortly afterwards.

The winch was in really good shape except that it had been sitting far too long so seals and bearings needed replacing. The gears looked nearly new. This was a good find as most winches I have found are pretty well used. I will share the disassembly and restoration at a future time.

The installation was fairly straight forward. I found a couple original manuals that gave great details on all the controls and modifications needed. Be prepared as some parts will have to be made because they will not be available. The pins in the top of the transmission/differential case for the steering clutches will have to be pulled out and replaced with two new pins 3/8” longer. This is due in part to the top mounting bracket.

The brace between the fenders looked way to flimsy to add any real strength so I made a new one out of angle iron.

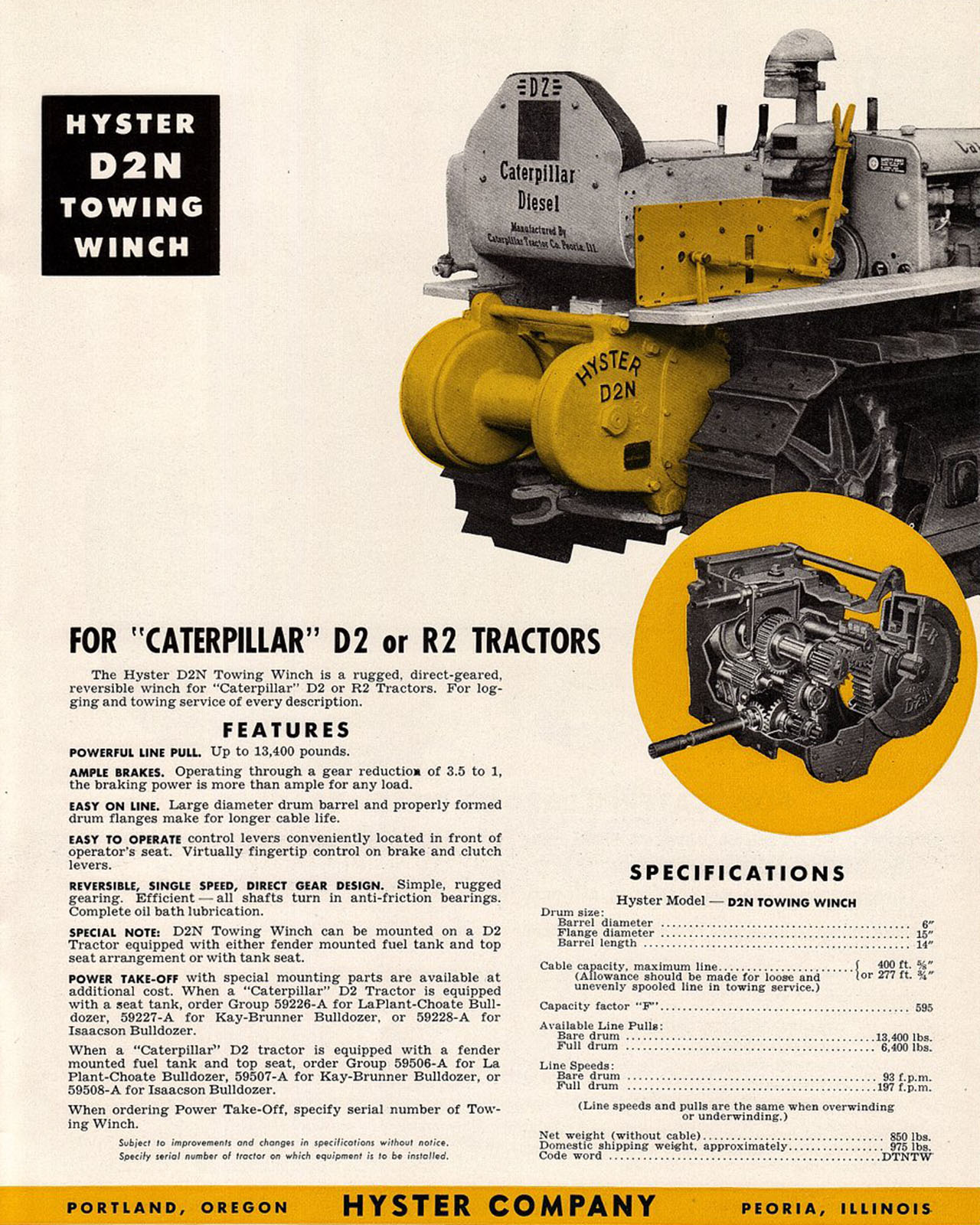

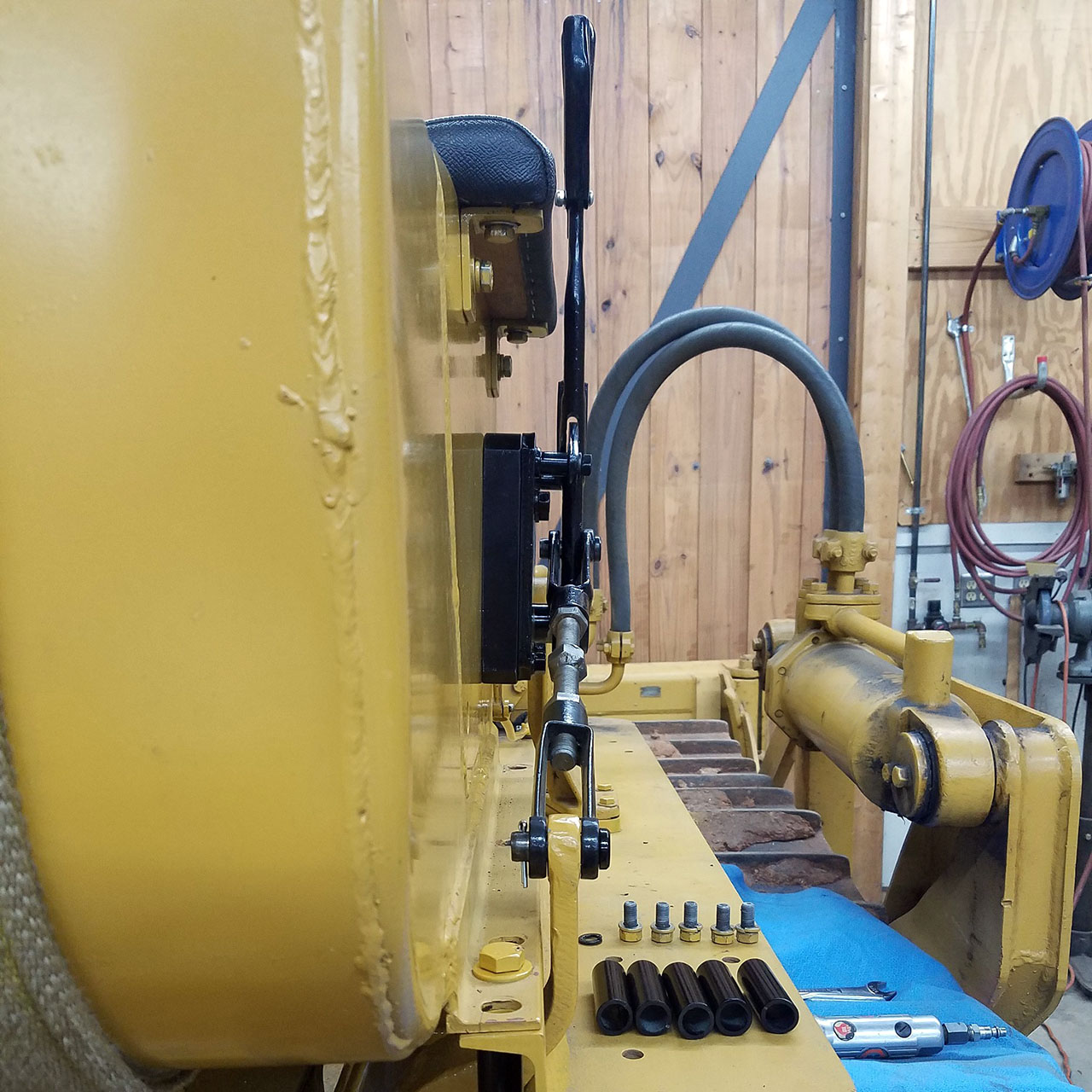

There were a few extra modifications I made that I felt strengthened and/or made it easier to use. I added a 1” plate to the side of the seat controls to get it more in line with the control lever coming off the winch. I also raised the blade control approximately 3/4” for easier use. I then added pipe between the flanges on the 3” channel risers for the seat bolts to go through. The reason for this was every seat mount flange on tractors I’ve seen with a winch mounted was cracked or split. I assumed it was vibration.

One challenge with a mounted winch is lubricating the final drives. I had to figure out a way to refill them without spilling gear oil on the shop floor so I cut a length of 1” PVC pipe and stuck a funnel in the end. It worked great!

Hyster D2 Towing Winch Advertisement

Removal of seat tank, covers and steering clutch pivot pins

Install top winch mount to tractor

Steering clutch pivot pins removed

New steering clutch pivot pins 3/8” longer

Cut fenders for clearance and controls

Install winch to tractor

Fabricate new under seat fender brace

Install brace, covers and selector bracket

Mount seat on 3” channel risers

Mount winch controls to seat

Different view of winch controls

Raise hydraulic blade control

View of Forward/neutral/reverse control

Another view of controls

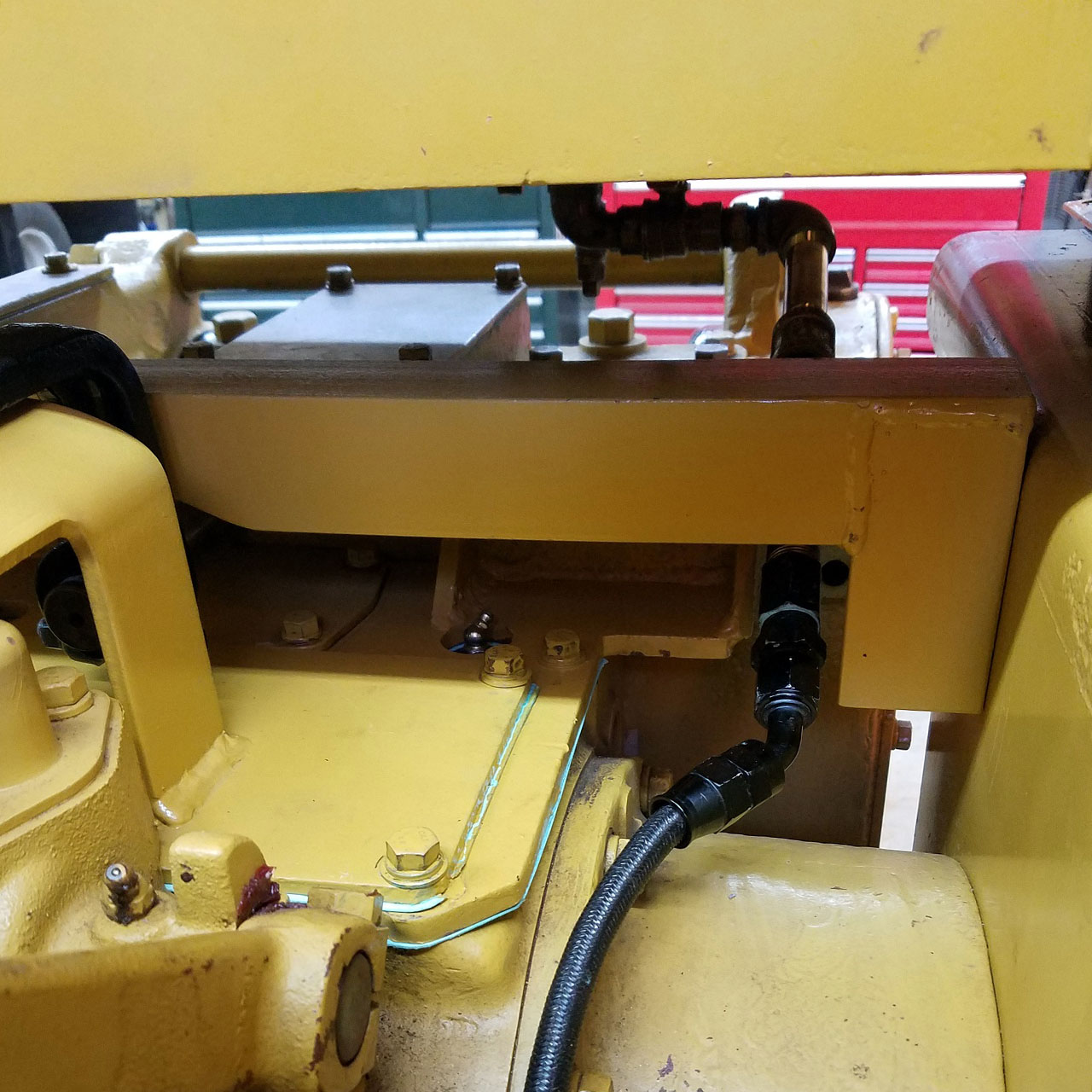

Fuel line install

Another view of fuel line

Another view of fuel line - I have since mounted a fuel filter in this location

Filling final drive

Adjusting winch brake

Finished install