Saturday Service. A large manufacture of "off the road" tires recently made a detailed study of tire maintenance on an earthmoving project which totaled 5 million tire miles. During this period, a rigid inspection and maintenance schedule was initiated. Additionally, haul roads were better maintained. The results were as anticipated: Increased tire life, decreased downtime. Previously tire inflation pressures were erratic. In fact only 48% of all the tires operated at recommended pressures. Twenty to twenty five pounds variation from recommended pressures was common. Cuts. or minor damage ad also been overlooked.

With the careful maintenance schedule, 90% of all tires operated within 5 psi of recommended pressure. Minor tire damage was quickly repaired, preventing further damage. Overall tire life increased by 46%, and on one size tire, an increase of 86% was recorded. These statistics, once again demonstrate the tremendous benefits of careful adherence to tire inspection and maintenance. Systematic and intelligent service by mechanics and operators will certainly bring about great improvements in extending tire life.

Proper Inflation is essential to long service life

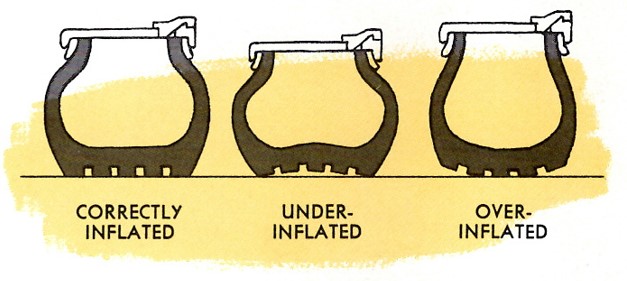

Let's talk about inflation. Proper inflation is one of the most important factors in tire care and it requires little time or equipment. Each tire is designed and built to permit a definite percentage of deflection (flattening) in a particular type of service. As loads increase of decrease, inflation pressures must follow in order to maintain the deflection rate which has been calculated to provide maximum cushioning and tire life. Over-inflation results in high cord stress and reduces resistance to blow outs from impacts. Underinflated tires are subject to increased deflection and excessive flexing. Operation of underinflated tires results in uneven or spotty tread wear, side wall radial cracks, ply separation, and loose or broken cords inside the tire.

Let's talk about inflation. Proper inflation is one of the most important factors in tire care and it requires little time or equipment. Each tire is designed and built to permit a definite percentage of deflection (flattening) in a particular type of service. As loads increase of decrease, inflation pressures must follow in order to maintain the deflection rate which has been calculated to provide maximum cushioning and tire life. Over-inflation results in high cord stress and reduces resistance to blow outs from impacts. Underinflated tires are subject to increased deflection and excessive flexing. Operation of underinflated tires results in uneven or spotty tread wear, side wall radial cracks, ply separation, and loose or broken cords inside the tire.

Rock ribbed tires give good traction and offer extra abrasion resistance.

When tires are operated in soft soil or sand, tire inflation pressures can be appreciably lower than those recommended for pavement or hard gravel surfaces. The reason for this is that the tire makes a full impression in the soft surface and thus the tire is "cradled" - preventing extreme deflection.

Make repairs at once

Now lets take a look at the repairs required on tires. A daily inspection for cuts, breaks, and sharp objects which might work into the casings good preventative maintenance practice. Such inspections could be performed at the same time as the inflation is checked. Repair at once all deep cuts which have penetrated into the cord body.

Failure to make regular inspections and to perform repairs when they are needed can result in unnecessary damage to the tires. Small rocks and dirt can get into shallow cuts and, if neglected, may gradually be pounded through the cord body. One simple method of preventing extensive damage is to clean out small cuts with a knife or with a bull-nosed rasp so a pocket cannot be formed which will catch rocks and allow them to work into the cord. If the tire has at least one deep cut that requires repair, then all smaller cuts may be quickly and cheaply repaired at the same time the major cut is fixed. Large breaks should not be repaired unless the tire is to be used for only light duty service work. Old tires with no more than 25% tread remaining are seldom economical for extensive repairs.

Another need for maintenance is evident on most haul roads. In most "off the road" projects the haul road may only be the tracks of the preceding dozer or scraper. In any event, the surface is mighty important as far as the service life of the tires is concerned. Unnecessarily steep grades, or sharp turns will increase tire slippage and result in fast abrasive wear. Imbedded or loose rocks increase the cutting and impact break hazards, and decrease the speed of operating. Maintaining a good haul road will usually pay a big dividend in the form of increased tire and vehicle life. Develop the habit of inspecting tires for any loss of air pressure or for damage. Punctures and slow leaks may develop anytime. Keep valve caps on tubes to prevent dirt from getting into the valve. Replace the valve cores whenever they show signs of leaking. Wipe of any oil or grease which may be on the tires. Tire life can be extended in may ways. An operator who is constantly aware of the cost of replacement tires can be a big help in reducing replacement costs. He can do this in two ways. One, by following the maintenance practices suggested here, and, two, by operating wheel equipment in such a manner as to achieve better than average tire life. Tire life can be extended. It takes a little work, but its worth it.

Tire tread is directional. The left rear is improperly installed and will not self clean.

All this information comes from the April 1954 edition of the Caterpillar Service Reporter.